Aluminum alloy is a metal, while an aluminum profile is a type of material. Aluminum profiles can be made of pure aluminum or aluminum alloy.

Aluminum alloy

Alloys of aluminum, e.g., aluminum-copper, aluminum-manganese, aluminum-zinc-magnesium-copper, and aluminum-copper-magnesium, are a combination of aluminum and various alloying components as suggested by their respective names.

Compared to pure aluminum, aluminum alloys tend to have superior mechanical and physical qualities, including process-ability, durability, versatility, aesthetics, and color.

The aerospace, aviation, automotive, shipbuilding, commercial, and machinery industries employ aluminum alloy extensively. Indeed, it’s the most popular non-ferrous structural material.

Depending on the production technique, alloys of aluminum can fall into the following categories:

Deformed aluminum alloy

Deformed aluminum alloy is produced under cold and hot pressure processing techniques such as extrusion and rolling, resulting in various profiles, including wires, plates, tubes, and rods. There are several types of deformed aluminum alloys.

Anti-rust aluminum

The anti-rust alloy of aluminum belongs to either the aluminum-magnesium or aluminum-manganese series. It’s usually used for fuel, tanks, containers, etc. It’s known for its excellent flexibility, mild strength and high corrosion resistance. It can be heat treated to improve its rust resistance.

Duralumin

Duralumin is a hard aluminum alloy containing aluminum, copper and magnesium. It is employed in producing instruments such as frames, girders, and air propellers. It’s a high-strength alloy but very vulnerable to corrosion. Its strength can be improved via ageing treatment or quenching.

Super-hard aluminum alloy

This alloy contains aluminum, magnesium, copper and zinc. It’s used to manufacture aircraft parts that must withstand a lot of force, e.g., girders and landing gear. However, it’s vulnerable to corrosion. Heat-treating can help improve its strength.

Wrought aluminum

Most wrought aluminum is made of alloys of aluminum, copper, silicon, and magnesium, or aluminum, nickel, copper, magnesium, and iron, which have strong thermoplasticity, resistance to corrosion, and excellent pressure processing capacity in hot environments.

Heat treatment can be used to produce the best metal. It is mainly used in aviation to create lightweight, durable, and intricate stampings and forgings such as conductor wheels and impellers.

Casted aluminum alloy

This aluminum alloy with outstanding casting performance may be split into the aluminum-silicon family, aluminum-copper family, aluminum-magnesium family, aluminum-zinc family, etc. It is produced using a variety of casting techniques and comes in a variety of shapes.

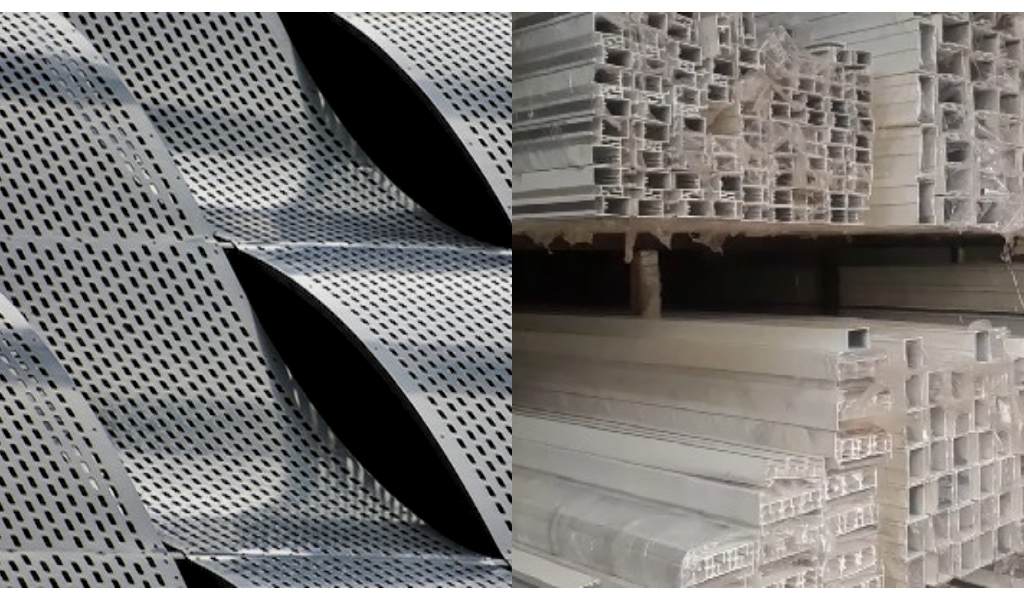

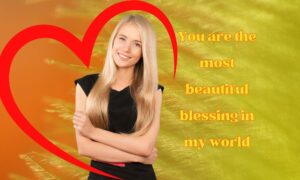

Aluminum profile

On the other hand, an aluminum profile is usually created by hot melting and extruding aluminum rods (pure or alloyed) into various cross-sectional shapes.

JMA aluminum profiles are commonly found in aluminum castings, space shuttle parts, electric and electrical parts, aluminum ceilings, doors, and windows.

Aluminum profiles typically need surface treatment to improve visual effects, increase corrosion resistance, and lengthen the service life.

Classification based on surface treatment includes:

- Anodized aluminum profile

- Powder-coated aluminum profile

- Using powder coating machines

- Electrophoresis aluminum profile

- Wood grain effect aluminum profile

- Fluorocarbon paint aluminum profile

Features of aluminum profiles include:

Corrosion resistance

Aluminum profiles have a density below 2.7g/cm3, making them less dense than copper (8.93g/cm3) and steel (7.83g/cm3) by nearly a third. Aluminum profiles exhibit good corrosion resistance in most environmental situations, including saltwater, air petrochemicals, and several chemical systems.

Good electrical conductivity

When weights are equal, aluminum has approximately twice the conductivity of copper. It makes it popular for use to manufacture various electrical and electronic accessories.

Decent thermal conductivity

For the production of radiators, heat sinks, and cooking and heating appliances, aluminum alloy is preferred because it conducts 50 to 60% more heat than copper material of the same weight.

Non-ferromagnetic

An essential requirement for the electrical and electronic sectors’ materials is non-ferromagnetism. It conducts electricity without interfering with the flow of charge. It’s also non-combustible and valuable in applications involving contact or handling explosive or flammable materials.

Recyclability

Aluminum is incredibly recyclable, and the recycled metal has identical properties to those of primary aluminum.

These characteristics make the aluminum profile material suitable for

- Furniture, doors, curtain walls, and windows

- Aircraft parts and other aviation equipment

- CPU radiator and unique heatsinks

- Construction of medical equipment

If you are after the best aluminum and aluminum materials, get in touch with JMA Aluminium. We are one of the leading producers of aluminum formwork. We have previously supplied materials for projects such as the Great Hall of the People, Tokyo Post Building, Hong Kong International Business Center, Beijing Olympic Village, California Federal Government Building, and Dubai Tower.